Specifications

Chemical Composition

| Carbon | : | 2.35% |

| Manganese | : | 0.30% |

| Silicon | : | 0.25% |

| Chromium | : | 11.50% |

| Vanadium | : | – |

Treatment

D3 is supplied in the annealed and machinable condition. Re-annealing will only be necessary if the steel has been forged or hardened by the toolmaker. To anneal, heat slowly and uniformly to 900°C. Soak for three to four hours and allow to cool in the furnace to room temperature. Re-heat to 800-1040°C and again soak for three to four hours. Allow to cool in the furnace to room temperature.

Quality Assured Supply

1.2080 (D3) tool steel is supplied in accordance with our ISO 9001 : 2008 registration.

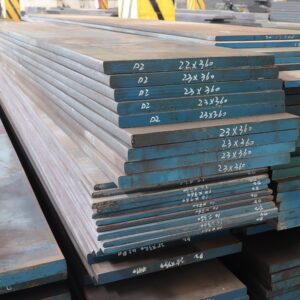

Form of Supply

Available in round bar, flat bar, plate and block. Diameters can be sawn to your required lengths as one offs or multiple cut pieces. Rectangular pieces can be sawn from flat bar or plate to your specific sizes.

Contact our experienced sales team who will assist you with your D3 tool steel enquiry.

Applications

D3 is suitable for applications such as complex blanking and forming tools for long runs and for hard and abrasive materials. It is commonly used for other applications such as brick and tile mould liners, master hobs for cold hobbing plastic moulds, tabletting punches and sleeves for corrosive powders.