Specifications

Chemical Composition

| Carbon | : | 0.40% |

| Manganese | : | 1.50% |

| Molybdenum | : | 0.20% |

| Chromium | : | 1.90% |

| Nickel | : | 1.00% |

Treatment

The preheating of measuring and cutting tool steel is spheroid zing annealing, final heat treatment is quenching + low temperature tempering and hardness after heat treatment can reach 60~65HRC. When heat treat tool steel grades consideration should be given to hardening temperature, including ratio of heating, cooling and soaking times which will differ due to factors such as the shape and size of each chemical component. Other considerations during heat treatment include the type of furnace, quenching medium and work piece transfer facilities.

Quality Assured Supply

1.2738 tool steel is supplied in accordance with our ISO 9001 : 2008 registration.

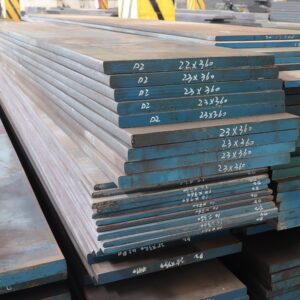

Form of Supply

Available in plates. Rectangular pieces can be sawn from flat bar or plate to your specific sizes.

Sheets availability are up to 21mm – 600mm.

Contact our experienced sales team who will assist you with your 1.2738 tool steel enquiry.

Applications

Die steel for plastic moulds with a thickness of about 400mm plus, if uniform hardness, elevated toughness and polishability is required in the contour as well. Moulds for TV housings and rear walls, copier housing, shock absorber moulds, moulds for dashboards and large outside body parts, waste bin moulds, pressure casting frames.