Specifications

Chemical Composition

| Carbon | : | 0.40% |

| Manganese | : | 1.00% |

| Silicon | : | 0.40% |

| Chromium | 1.20% | |

| Molybdenum | : | 1.00% |

Treatment

Heat treatment temperatures, including rate of heating, cooling and soaking times will vary due to factors such as the shape and size of each 2767 steel component. Other considerations during the heat treatment process include the type of furnace, quenching medium and work piece transfer facilities. Please consult your heat treatment provider for full guidance on heat treatment of tool steels.

Quality Assured Supply

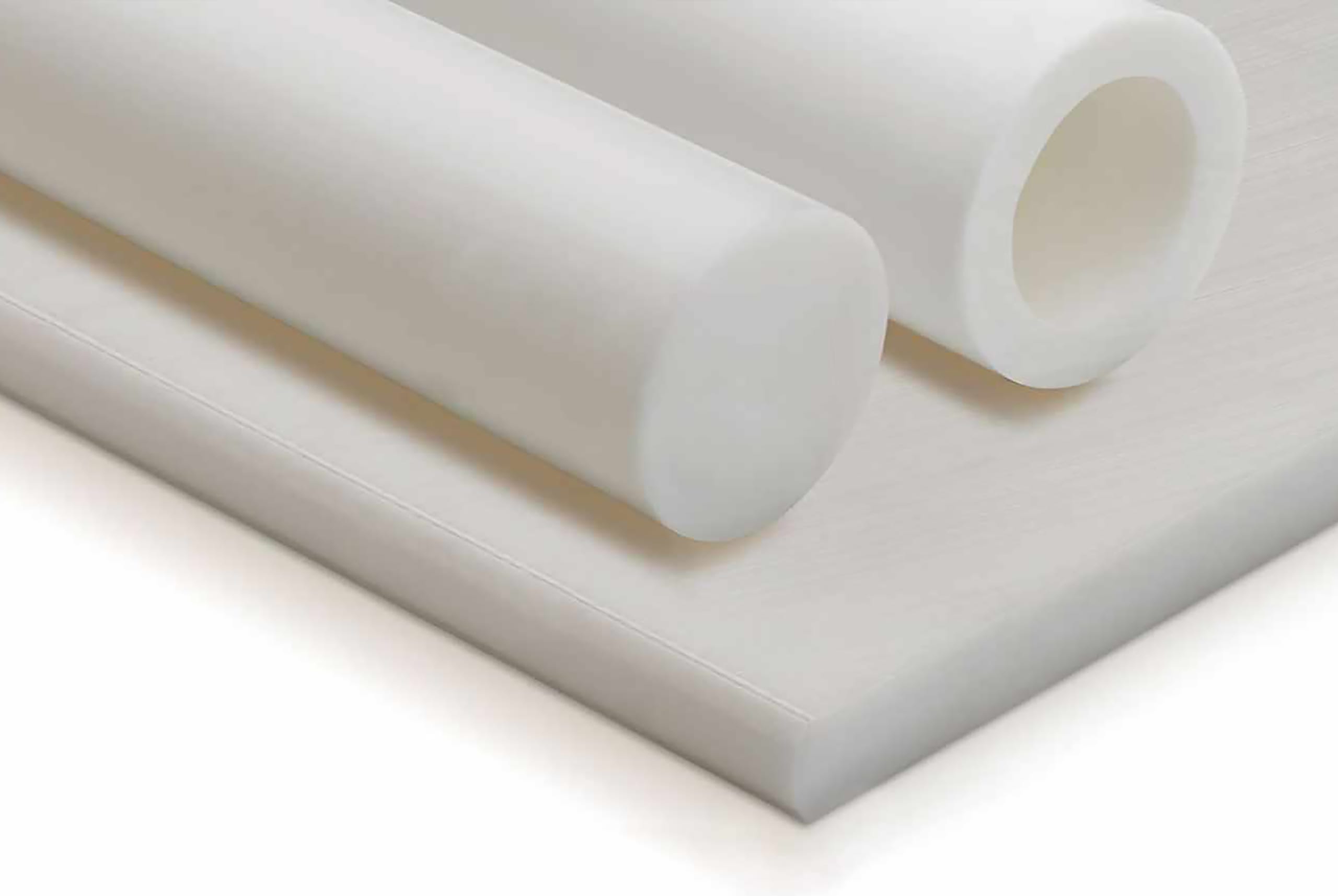

POM is supplied in accordance with our ISO 9001 : 2008 registration.

Form of Supply

Supreme Steel are stockholders and suppliers of POM round bar and flat sections which can be sawn cut to your required sizes.

Contact our experienced sales team who will assist you with your POM enquiry.

|

|

|

| Plate | Flat | Diameter |

Applications

Pump and valve components

Close tolerance precision parts

Thin wall parts

Electronic components

Gears

Bearings

Bushings

Rollers

Fittings

Electrical insulator parts

Analysis

- Very low water absorption.

- Great resistant to dilute acids, solvents and cleaning agents.

- Very tough.

- Great electrical insulation.

- Easily weldable.

| Density | 0.92 g/cm^3 |

|---|---|

| Colour | Natural/Beige Grey/Black |

| Chemical Designation | PP (Polypropylene) |

Mechanical Properties

| Properties (°C) | Result | Unit | Parameter | Norm used |

|---|---|---|---|---|

| Modulus of Elasticity | 2000 | MPa | 1 mm/min | DIN EN ISO 527-2 |

| Tensile Strength | 33 | MPa | 50 mm/min | DIN EN ISO 527-2 |

| Tensile Strength at Yield | 33 | MPa | 50 mm/min | DIN EN ISO 527-2 |

| Elongation at Yield | 5 | % | 50 mm/min | DIN EN ISO 527-2 |

| Elongation at Break | 65 | % | 50 mm/min | DIN EN ISO 527-2 |

| Flexural Strength | 54 | MPa | 2 mm/min | DIN EN ISO 178 |

| Modulus of Elasticity (flex test) | 1800 | MPa | 2 mm/min, 10 N | DIN EN ISO 178 |

| Compression Strength | 15/26 | MPa | 1%/2%. 5 mm/min, 10 N | DIN EN ISO 604 |

| Compression Modulus | 1600 | MPa | 5 mm/min, 10 N | EN ISO 604 |

| Impact Strength (Charpy) | 140 | Kj/m^2 | Max. 7,5j | DIN EN ISO 179-1EU |

| Notched Impact Strength (Charpy) | – | Kj/m^2 | Max. 7,5j | DIN EN ISO 179-1EU |

| Ball Indentation Hardness | 100 | MPa | – | ISO 2039-1 |

Thermal Properties

| Properties (°C) | Result | Unit | Parameter | Norm used |

|---|---|---|---|---|

| Glass Transition Temperature | -10 | °C | – | DIN 53765 |

| Melting Temperature | 165 | °C | – | DIN 53765 |

| Service Temperature | 140 | °C | Short Term | – |

| Service Temperature | 100 | °C | Long Term | – |

| Thermal Expansion | 13 | 10^-5 K^-1 |

23-60°C Long | DIN EN ISO 11359-1;2 |

| Thermal Expansion | 14 | 10^-5 K^-1 |

23-100°C Long | DIN EN ISO 11359-1;2 |

| Specific Heat | – | J/(g+K) | – | ISO 22007-4:2008 |

| Thermal Conductivity | – | W/(K+m) | – | ISO 22007-4:2008 |

Electrical Properties

| Properties (°C) | Result | Unit | Parameter | Norm used |

|---|---|---|---|---|

| Surface Resistance | – | Ω | – | DIN IEC 60093 |

Miscellaneous Properties

| Properties (°C) | Result | Unit | Parameter | Norm used |

|---|---|---|---|---|

| Water Absorption | 0,01/0,02 | % | 24h/96h (23°C) | DIN EN ISO 62 |

| Resistance to Hot Mater/Bases | (+) | – | – | – |

| Resistance to Weathering | – | – | – | – |

| Flammability (UL94) | HB | – | According to | DIN IEC 60995-11-10 |