Specifications

Chemical Composition

| Carbon | : | 0.28-0.33% |

| Manganese | : | 0.40-0.60% |

| Silicon | : | 0.10-0.35% |

| Nickel | : | 0.25% max |

| Chromium | : | 0.90-1.10% |

| Molybdenum | : | 0.15-0.25% |

| Phosphorous | : | 0.035% max |

| Sulphur | : | 0.040% max |

Mechanical Properties

| Tensile KSI |

0.2% Proof Stress KSI |

Elongation % |

Reduction of Area % |

Hardness HRc |

Hardness Brinell |

|

|---|---|---|---|---|---|---|

| Min | 95 | 75 | 20 | 40 | 18 | 217 |

| Max | 130 | 110 | – | – | 22 | 235 |

(*at room temperature heat treated to 18-22HRc)

Certifications & QA

AISI 4130 alloy steel is available with a cast and analysis certificate or a BS EN 10204 3.1 mill certificate, please request when placing any orders. AISI 4130 round bar is supplied in accordance with our ISO 9001 : 2008 registration.

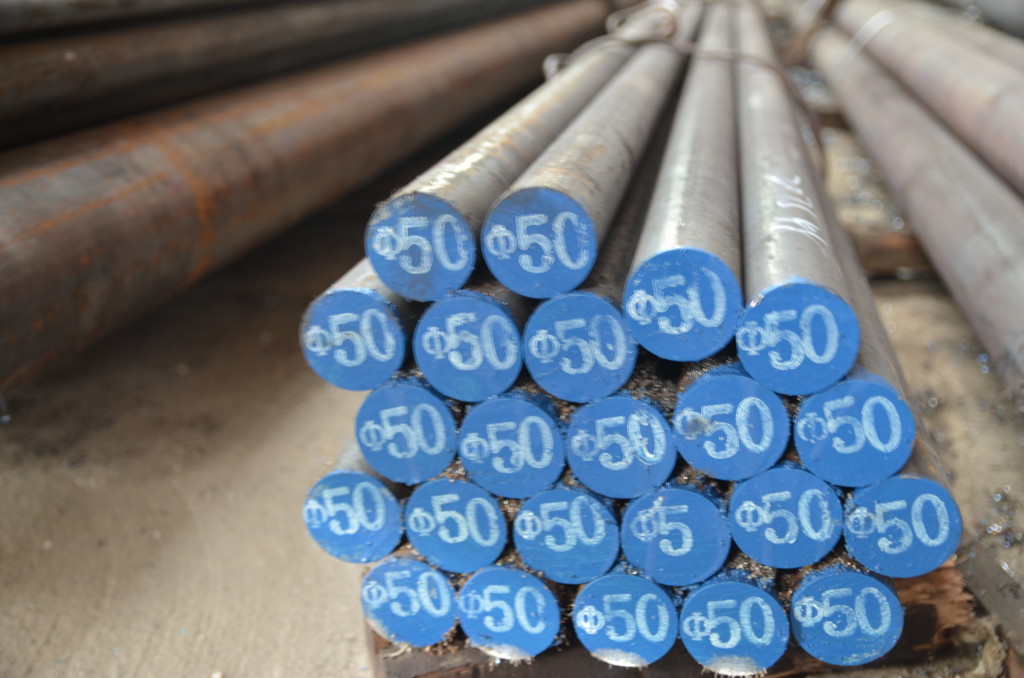

Form of Supply

Supreme Steel are AISI 4130 steel stockholders and suppliers of round bar. Diameters can be supplied as full bar lengths or cut blanks. AISI 4130 ground steel bar can be supplied, providing a high tensile alloy steel precision ground bar to tight tolerances.

Diameters availability are up to 50⌀ – 366⌀.

Contact our experienced sales team who will assist you with your AISI 4130 steel enquiry.

Applications

AISI 4130 is widely used for a variety of applications in the oil and gas sector. Typical applications include components such as valve bodies, pumps and fittings.