Specifications

Chemical Composition

| Chromium | : | 4.75 – 5.50% |

| Molybdenum | : | 1.10 – 1.75% |

| Carbon | : | 0.32 – 0.45% |

| Manganese | : | 0.20 – 0.50% |

| Silicon | : | 0.80 – 1.80% |

| Vanadium | : | 0.80-1.20% |

| Sulfur | : | 0.030%max |

| Phosphorous | : | 0.030%max |

| Iron | : | Balance |

Treatment

Forging temperature (start) is in range of 1095-1135°C. Forging temperature (finish) is 925°C min. Annealing temperature is in range of 845-870°C. Stress relieving temperature is in range of 650.675°C. Hardening temperature is in range of 1010-1025°C. Tempering temperature depends upon hardness and other requirements.

Quality Assured Supply

H13 (1.2344) tool steel is supplied in accordance with our ISO 9001 : 2008 registration.

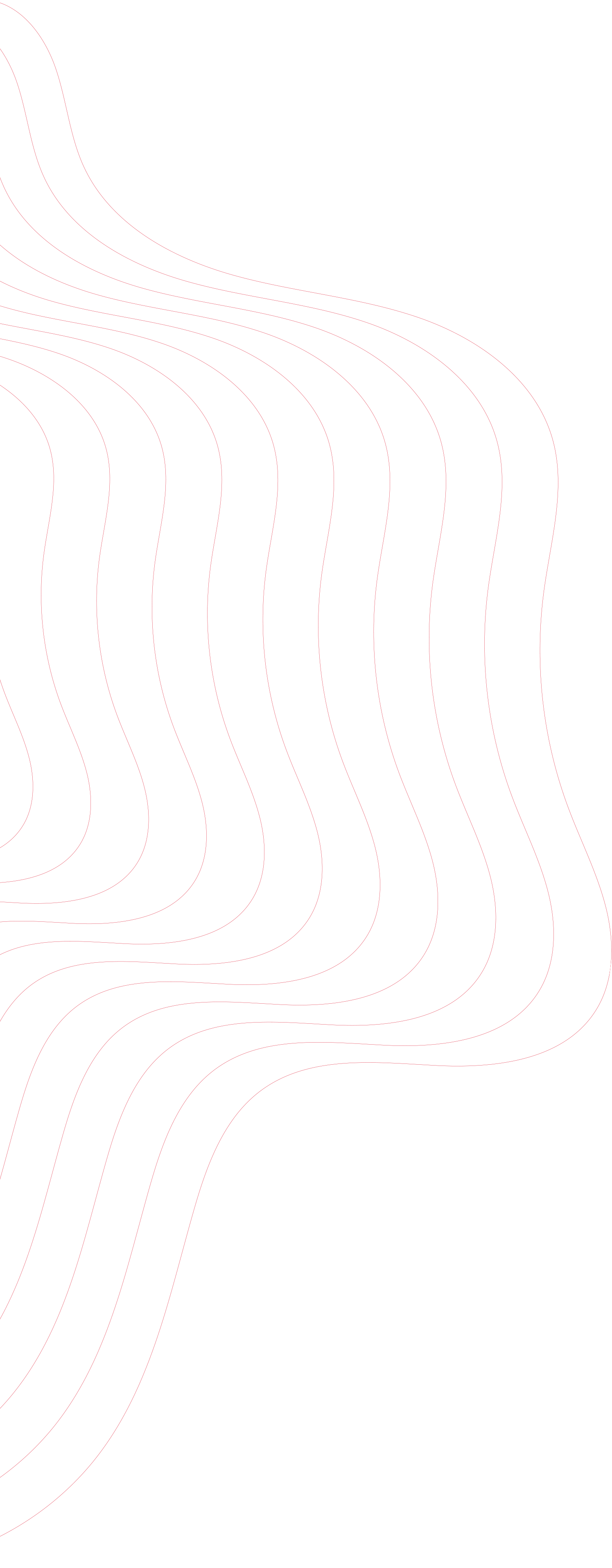

Form of Supply

Supreme Steel are stockholders and suppliers of H13 (1.2344) tool steel round bar and flat sections which can be sawn cut to your required sizes.

Diameters availability are up to 4⌀ – 333⌀.

Sheets availability are up to 20mm – 225mm.

Contact our experienced sales team who will assist you with your H13 (1.2344) tool steel enquiry.

Applications

Typical applications include die casting dies for aluminium, magnesium and zinc, extrusion dies for aluminium and brass, liners, mandrels, pressure pads, followers, bolsters, die cases, die holders and adaptor rings for copper and brass extrusion. H13 (1.2344) is used to produce hot stamping and press forge dies, split hot heading dies, gripper dies, hot punching, piercing and trimming tools. Other applications include plastic moulds, shear blades for hot work and hot swaging dies.