Specifications

Chemical Composition

| Carbon | : | 0.40% |

| Manganese | : | 1.00% |

| Silicon | : | 0.40% |

| Chromium | : | 1.20% |

| Molybdenum | : | 1.00% |

Treatment

Heat treatment temperatures, including rate of heating, cooling and soaking times will vary due to factors such as the shape and size of each P20 steel component. Other considerations during the heat treatment process include the type of furnace, quenching medium and work piece transfer facilities. Please consult your heat treatment provider for full guidance on heat treatment of P20 tool steel.

Quality Assured Supply

P20 tool steel is supplied in accordance with our ISO 9001 : 2008 registration.

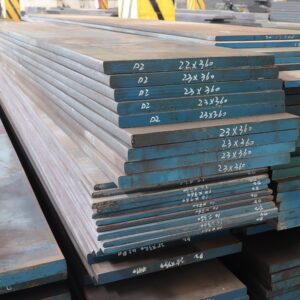

Form of Supply

Diameters in P20 can be sawn to your required lengths as one offs or multiple cut pieces. Rectangular pieces can be sawn from flat bar or plate to your specific sizes.

Diameters availability are up to 30⌀ – 280⌀.

Sheets availability are up to 20mm – 850mm.

Contact our experienced sales team who will assist you with your P20 tool steel enquiry.

Applications

P20 tool steel is ideally suited for the production of plastic moulds. Typical applications include die holders, zinc die casting dies, backers, bolsters and injection moulds. The versatility of P20 tool steel with its high tensile characteristics enables uses for a variety of other applications such as shafts, rails and wear strips